Understanding Scope 1, 2, and 3 Emissions

Beginner's guide to emissions

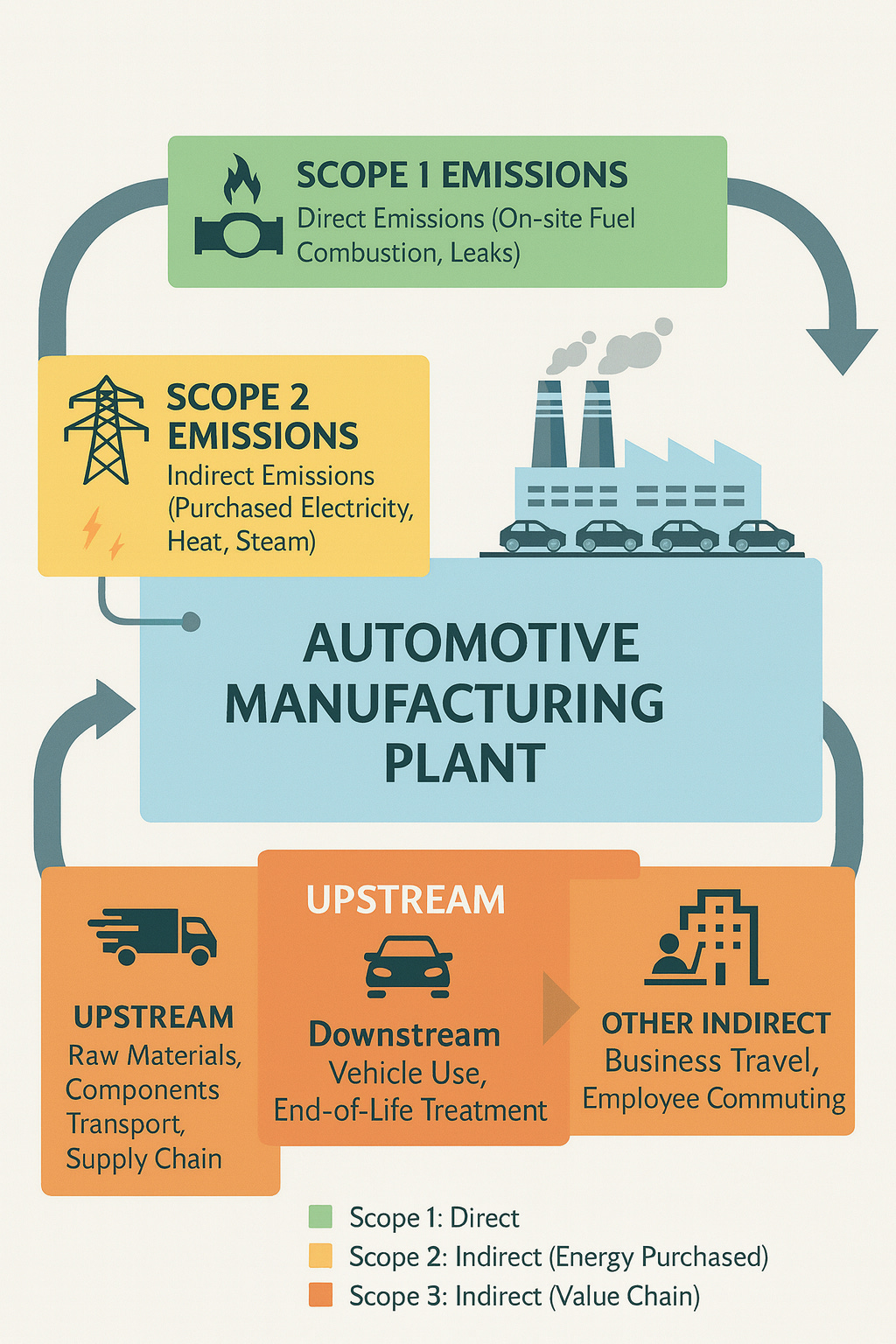

Imagine you work for a large automotive manufacturer like Volkswagen or BMW. Your CEO has just announced an ambitious goal to become carbon neutral by 2040, and you’ve been asked to help measure the company’s carbon footprint. You sit down with your laptop, ready to start counting emissions, but quickly realize a puzzling question: where do you even begin? Do you only count the emissions from your factories? What about the electricity you buy? And what about all that steel and aluminum your suppliers produce for you?

This is where understanding Scope 1, 2, and 3 emissions becomes essential. These three categories help you create a complete picture of your company’s climate impact, much like how a financial audit examines every aspect of your business finances rather than just what’s in the company bank account.

Scope 1: The Emissions You Can See

Let’s start with your automotive company’s Scope 1 emissions. These are the direct emissions coming from sources that your company owns or directly controls. Walk through one of your manufacturing plants, and you’ll encounter many of these sources firsthand.

Picture the massive paint shop where car bodies receive their glossy finish. The ovens that cure the paint run on natural gas, and when that gas burns, it releases carbon dioxide directly into the atmosphere. That’s a Scope 1 emission. Now walk over to the testing facility where engineers are running newly assembled vehicles through quality checks. The exhaust coming from those test vehicles represents another Scope 1 emission. Move to the parking lot, and you’ll see the company’s fleet of delivery trucks transporting parts between facilities. The diesel they burn creates more Scope 1 emissions.

The defining characteristic of Scope 1 is simple: if the combustion or chemical process happens on your property or in equipment you own, it’s a Scope 1 emission. Your company has direct control over these sources, which means you can directly decide to upgrade equipment, switch fuels, or modify processes to reduce them. This direct control makes Scope 1 emissions both the easiest to measure accurately and often the most straightforward to reduce.

Scope 2: The Invisible Partner in Your Operations

Now let’s consider your automotive company’s Scope 2 emissions, which are slightly less visible but equally important. Walk back into that same manufacturing plant, but this time focus on the thousands of robotic arms welding car frames together, the conveyor belts moving components through the assembly line, and the bright LED lights illuminating every corner of the facility. None of these directly burn fuel or release emissions on site, yet they’re all consuming enormous amounts of electricity.

That electricity had to come from somewhere. Perhaps it came from a coal-fired power plant two hundred kilometers away, or maybe from a natural gas facility in a neighboring state, or ideally from a wind farm in the countryside. Regardless of the source, generating that electricity produced emissions, and those emissions are attributed to you as Scope 2 because you’re the customer consuming that energy.

Here’s why this matters for your automotive company: modern car manufacturing is incredibly electricity-intensive. Your stamping presses shape metal body panels using tremendous electrical force. Your paint shop requires powerful ventilation systems. Your clean rooms where electronic components are assembled need precise climate control running constantly. Even though you might pride yourself on running a clean factory with no visible smokestacks, you’re still responsible for significant emissions happening at power plants elsewhere in the grid.

The interesting aspect of Scope 2 emissions is that while you don’t control the power plants, you do control your consumption choices. Your company can decide to purchase renewable energy contracts, install solar panels on factory roofs, or improve energy efficiency throughout your operations. These decisions directly impact your Scope 2 footprint, even though the actual emissions happen off your property.

Scope 3: The Hidden Majority of Your Impact

This is where the picture becomes much more complex for your automotive company, because Scope 3 typically represents the largest portion of emissions by far. Let’s trace the journey of a single vehicle to understand why.

Begin upstream, long before any car reaches your assembly line. Your suppliers are mining iron ore in Australia and bauxite in South America to create the steel and aluminum that form the vehicle structure. Smelting these metals is extremely energy-intensive, producing massive emissions. Chemical companies are manufacturing the polymers for your dashboard, door panels, and bumpers. Glass manufacturers are producing your windshields. Electronics suppliers are fabricating the semiconductors for your infotainment systems and safety features. Tire manufacturers are vulcanizing rubber. Every single component arriving at your factory carries with it an embedded carbon footprint from its production, and all of these upstream emissions fall into your Scope 3 category.

But Scope 3 doesn’t stop at your factory gates. Think about your employees commuting to work each day. If ten thousand employees drive personal vehicles to your plant every morning, those emissions are part of your Scope 3. Consider business travel when your engineers fly to supplier facilities for quality inspections, or when your sales team travels to auto shows around the world.

Now follow the vehicle downstream after it leaves your factory. The car gets loaded onto a transport truck, then perhaps onto a cargo ship if it’s being exported, creating distribution emissions. Eventually it reaches a dealership, which uses energy to operate its showroom. But the largest downstream Scope 3 emissions by far come from what’s called “use of sold products.” When customers drive your vehicles over their typical fifteen-year lifespan, burning thousands of liters of fuel in the process, those emissions count as your Scope 3. For a traditional automotive manufacturer producing internal combustion vehicles, these use-phase emissions often represent eighty to ninety percent of the total carbon footprint.

Finally, at the end of the vehicle’s life, it gets dismantled and recycled, generating more emissions from the shredding, sorting, and reprocessing of materials. Even the final disposal of non-recyclable components in landfills contributes to your Scope 3 total.

Why These Categories Transform Your Strategy

Understanding these three scopes fundamentally changes how your automotive company approaches carbon reduction. If you only measured Scope 1 and 2 emissions, you might invest heavily in making your factories more efficient and celebrate achieving a fifty percent reduction in manufacturing emissions. That’s certainly progress, but you’d be overlooking the fact that those manufacturing emissions represent only about ten percent of your total impact.

The real transformation happens when you look at the complete picture. You realize that switching your product line from internal combustion vehicles to electric vehicles dramatically reduces your Scope 3 use-phase emissions. You discover that working with your steel suppliers to source material made with renewable energy or green hydrogen can significantly cut your upstream Scope 3. You find that designing vehicles with recycled materials and making them easier to disassemble reduces end-of-life emissions.

This comprehensive view also helps you prioritize investments. Perhaps you were considering spending ten million euros to install slightly more efficient heating in your factories, which would reduce Scope 1 emissions by two percent. But that same investment in collaborating with your top twenty suppliers to decarbonize their operations might reduce your Scope 3 by twenty percent. The scope framework helps you see where your money and effort will have the greatest climate impact.

Moreover, these distinctions matter for reporting and accountability. International standards like the Greenhouse Gas Protocol require companies to report Scope 1 and 2 emissions, while Scope 3 reporting is increasingly expected by investors and regulators, particularly in the European Union under new sustainability disclosure requirements. Your stakeholders want transparency about your full climate impact, not just the emissions within your direct control.

Moving Forward with Clear Categories

When you started this journey of measuring your automotive company’s carbon footprint, the task seemed overwhelming. But now you can see how these three scopes provide structure to your approach. You’ll begin by carefully measuring your Scope 1 emissions, tracking every cubic meter of natural gas burned and every liter of fuel consumed. You’ll calculate your Scope 2 by examining electricity bills and understanding the carbon intensity of your regional power grids. Then you’ll tackle the more challenging Scope 3 by engaging suppliers, analyzing product lifecycles, and estimating customer usage patterns.

Each scope requires different measurement methods, different reduction strategies, and different partnerships. But together, they give you the complete picture you need to set meaningful targets, track real progress, and ultimately transform your company’s relationship with climate change. The journey from confusion to clarity begins with understanding these fundamental categories, and now you have the framework to measure, manage, and reduce emissions across your entire value chain.